Four principles drive the design of this wardrobe. Longevity, flexibility, design for assembly and disassembly and lastly a legible aesthetic expressing structure. First is achieved through sturdy materials such as mild steel and birch ply. Second is achieved through flexible components allowing for customisation.

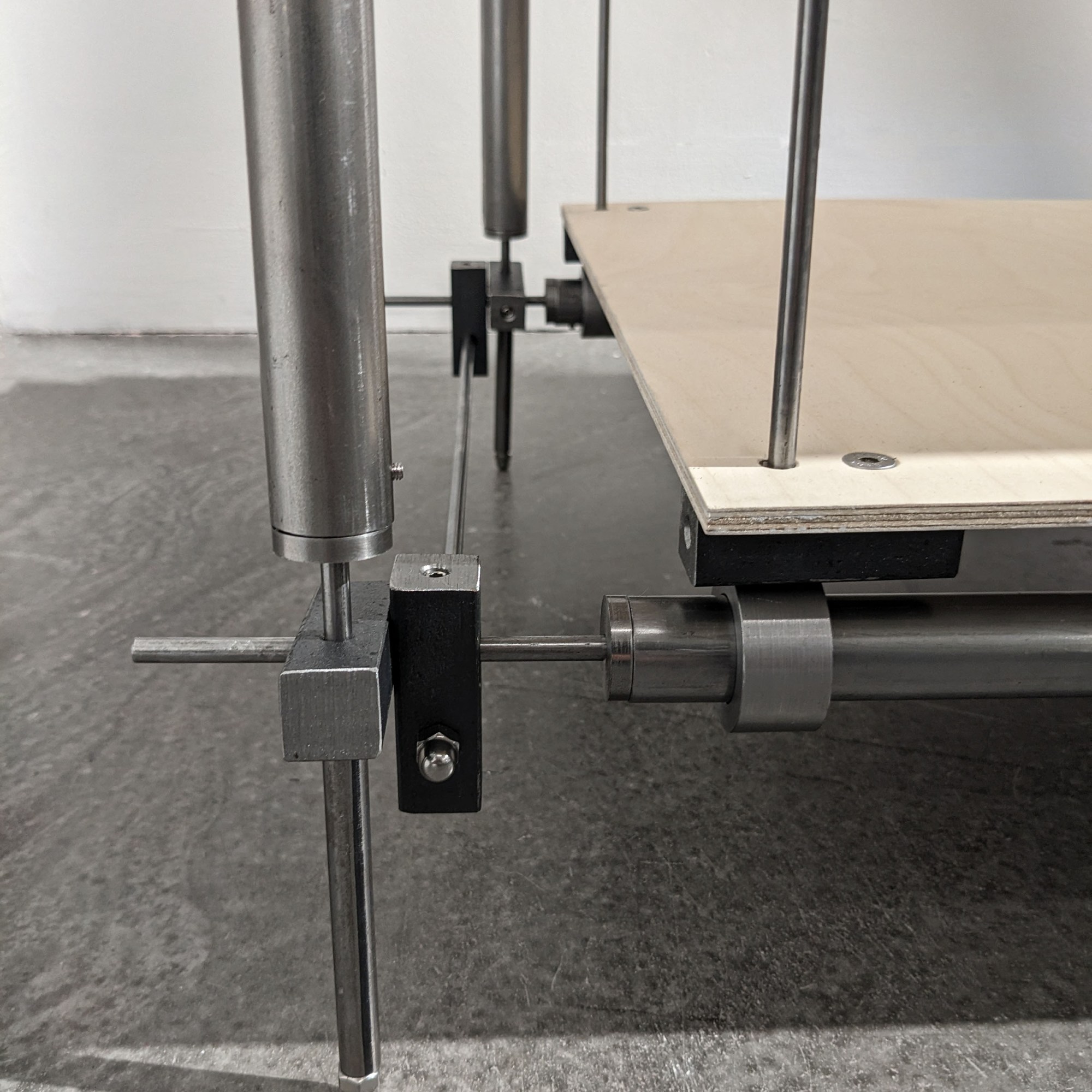

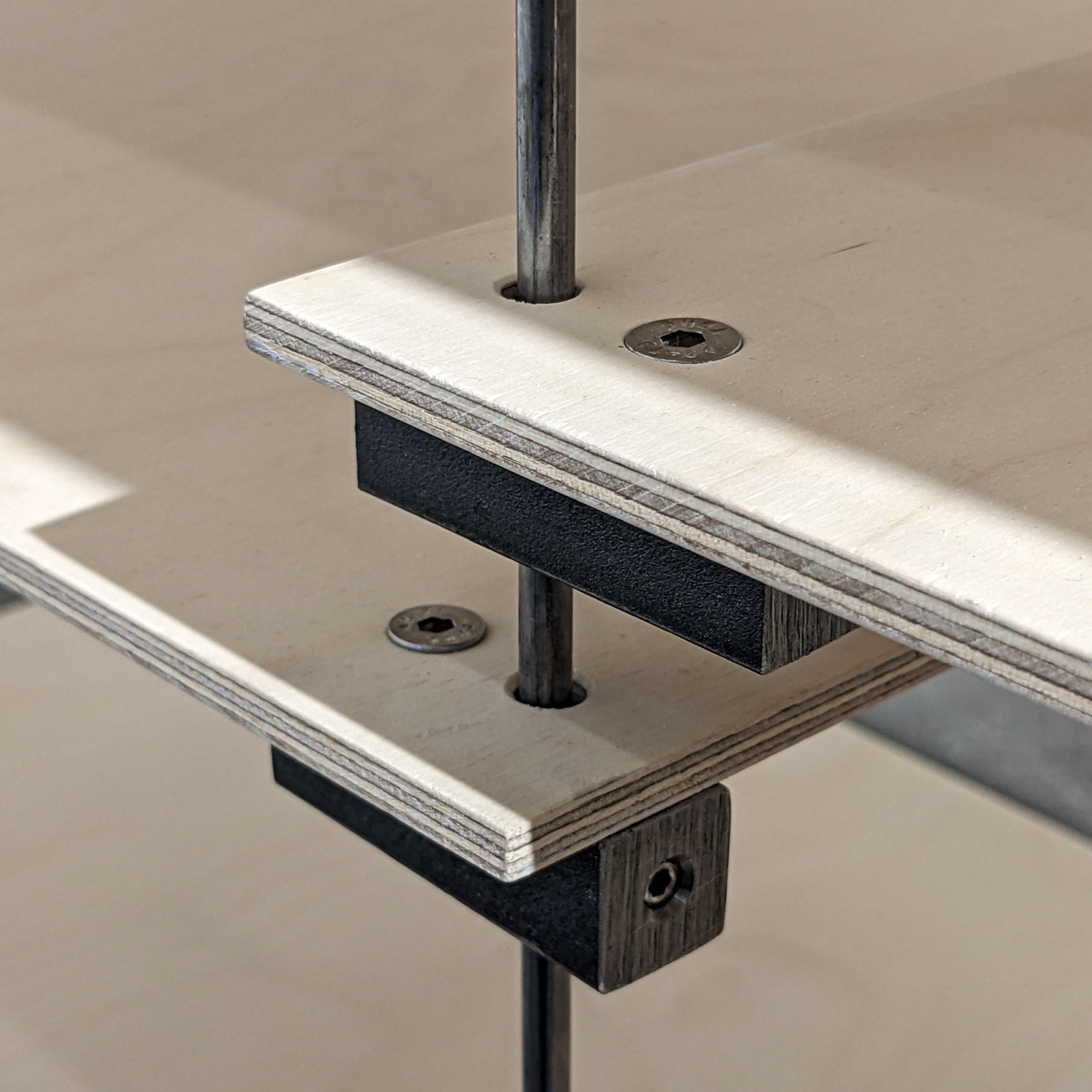

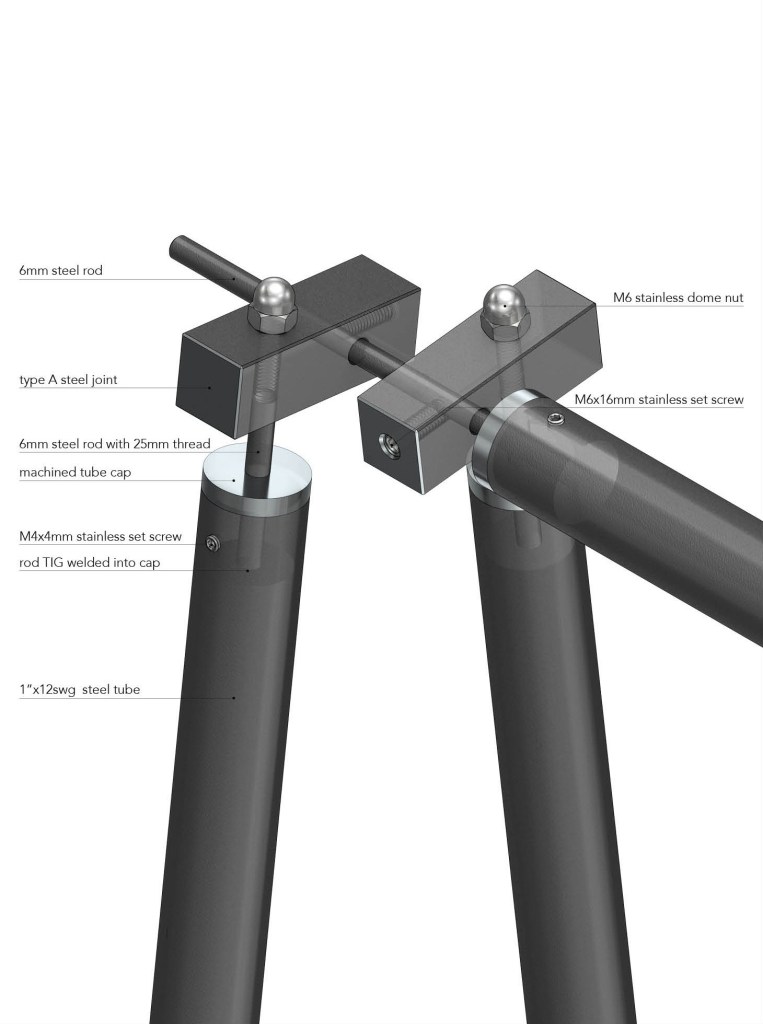

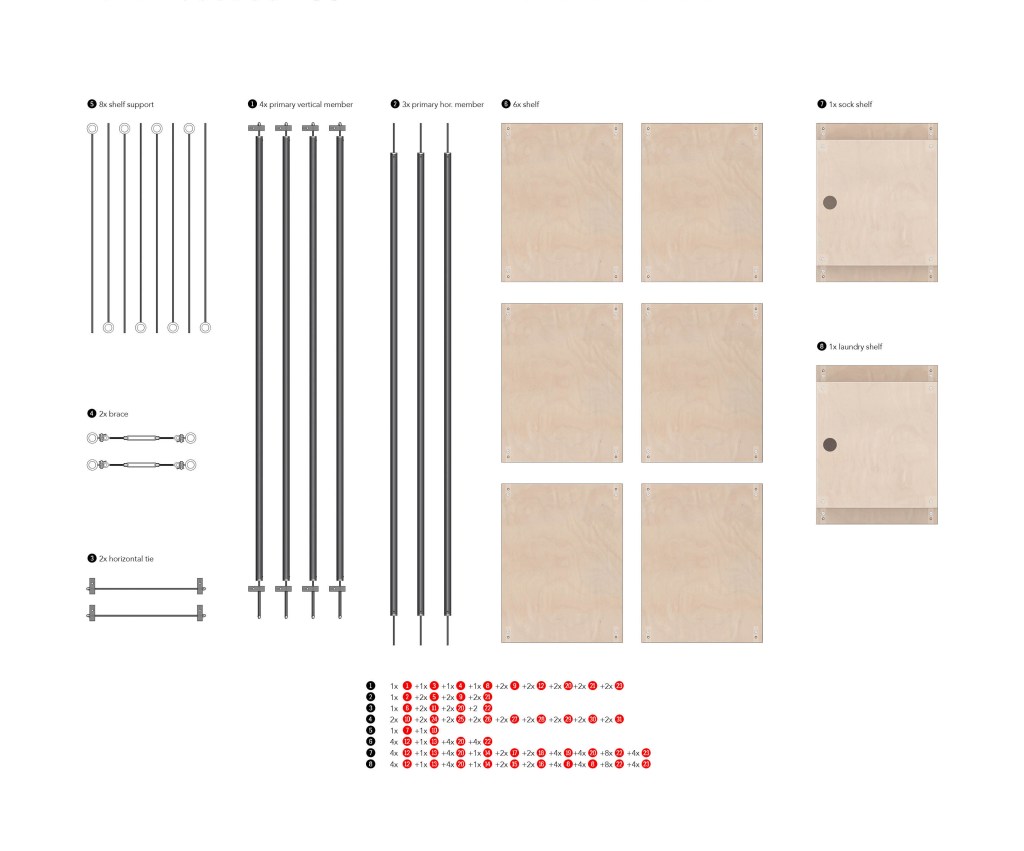

The design of the steel frame is driven by two concepts; to use only three types of joints and to reduce the size of the members at their ends, decreasing connection size while retaining buckling resistance. There are two types of joints made from 20x20mm steel bars; first are those allowing for two perpendicular connections, joining the primary frame members, the latter allow for two parallel connections, joining the shelves to the vertical rods. The third joint is the shaft collar connecting the shelves to the primary frame. Braces were introduced after physical testing and tied back to the design by employing the same shaft collars.

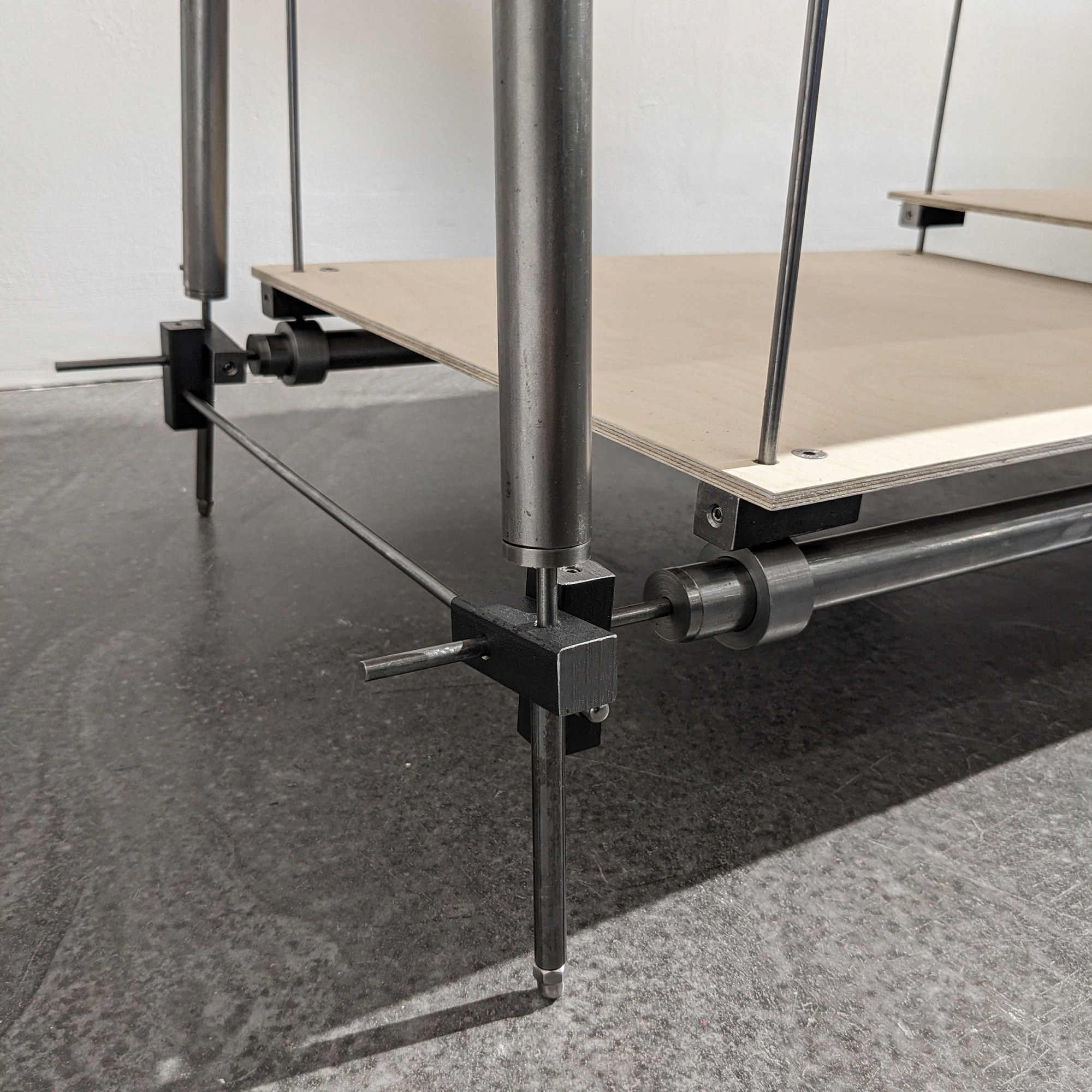

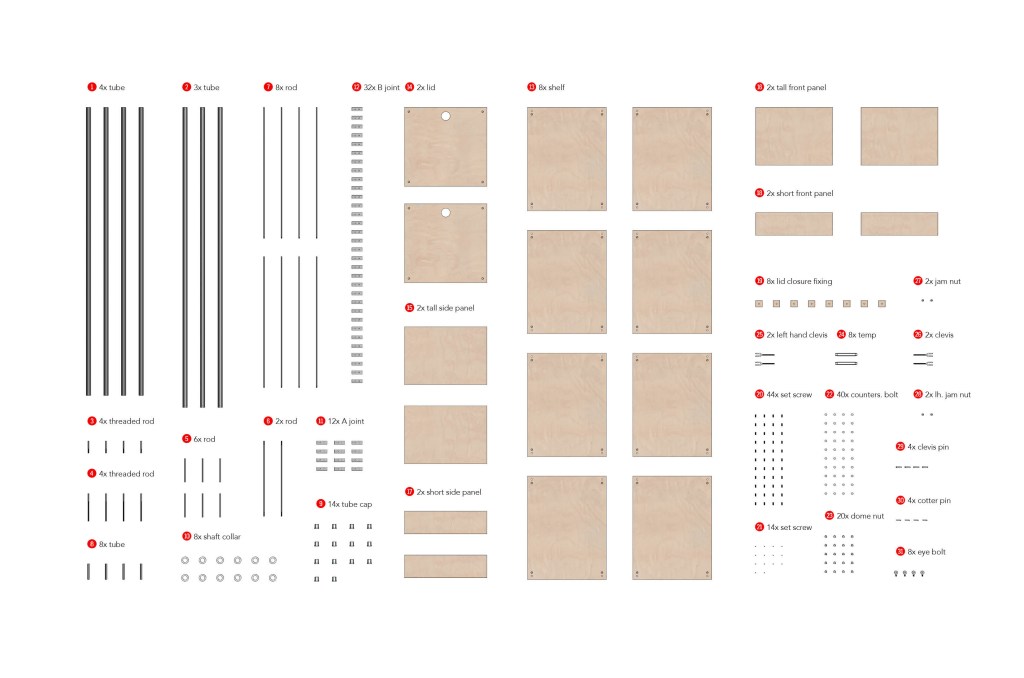

The structural hierarchy of this wardrobe consists of three systems. First is the primary steel frame, second is the shelf support system and third are the individual shelves. These may be adjusted to suit the user’s needs and preferences. The primary frame consists of nine sub-assemblies. These are four vertical tube assemblies, three horizontal tube assemblies and two brace assemblies. These may be assembled in about twenty minutes using a 10mm wrench, a 3mm Allen key and a calliper. The wrench is used to adjust the dome nuts, the Allen key to fasten the on cubic joints onto the 6mm using set screws, and the calliper ensures correct spacing. The Allen key and wrench may also be used to fasten the rigging screws.

The vertical shelving support rods are screwed by hand into the shaft collars on the primary frame to allow slight flexibility when inserting the shelf sub-assemblies. These are inserted from the top and fixed to the rods at the desired height using a 3mm Allen key. The above configuration ensures clothes of different lengths may be accommodated without wasting space.

Connection details